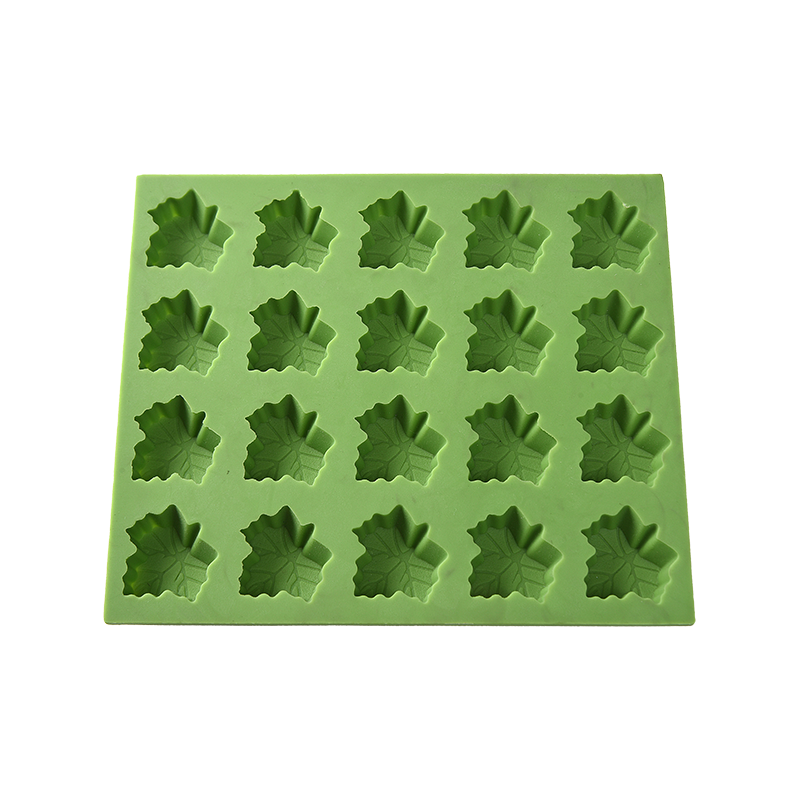

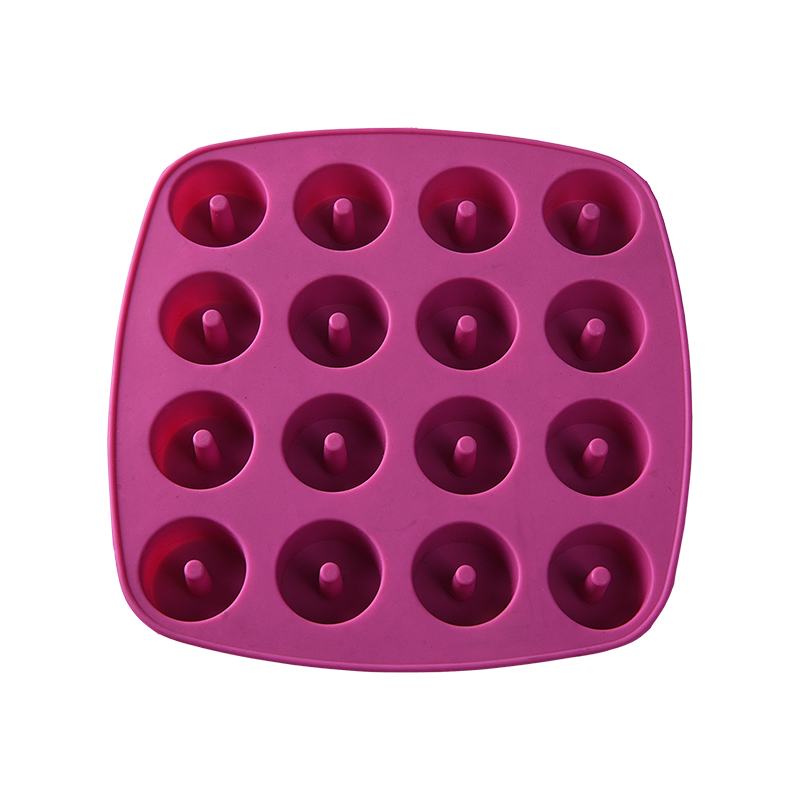

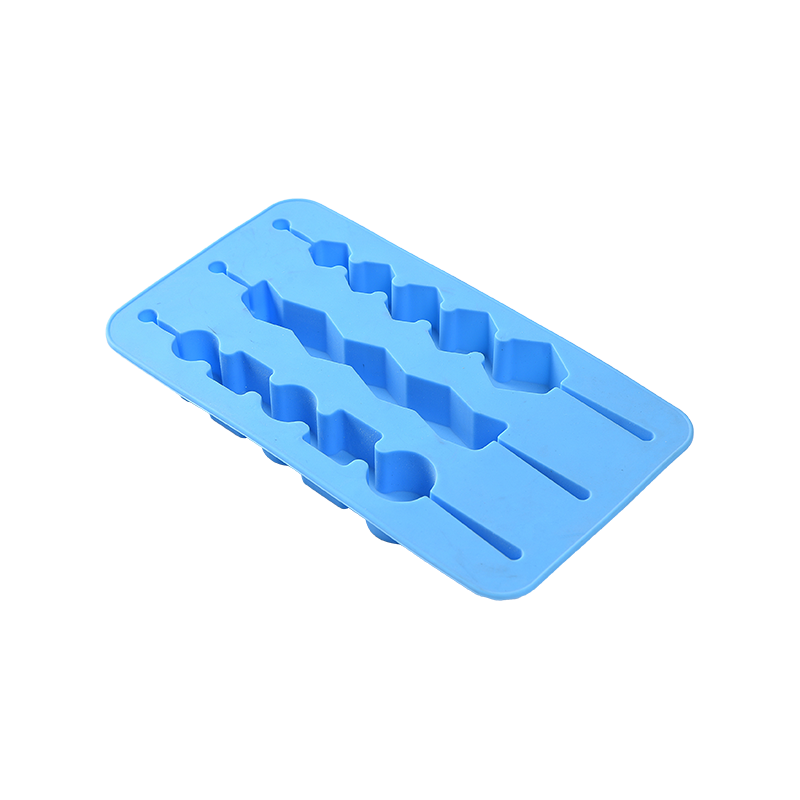

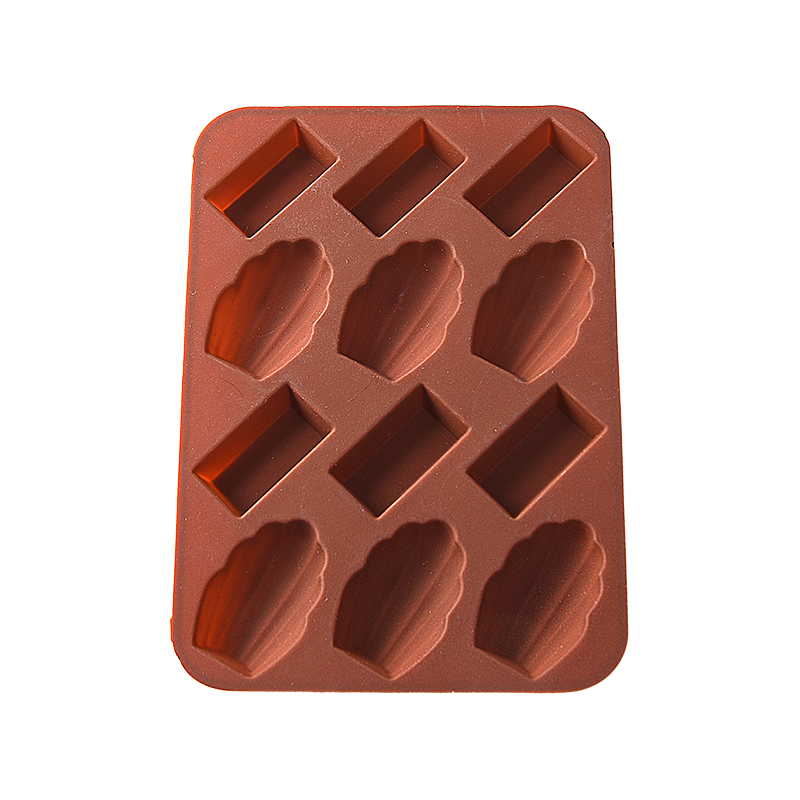

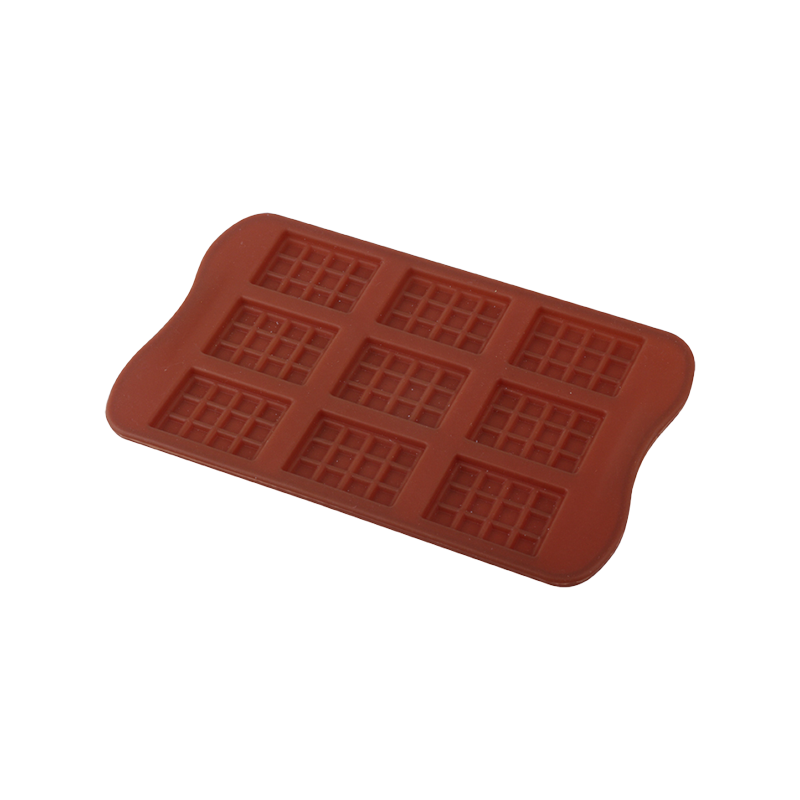

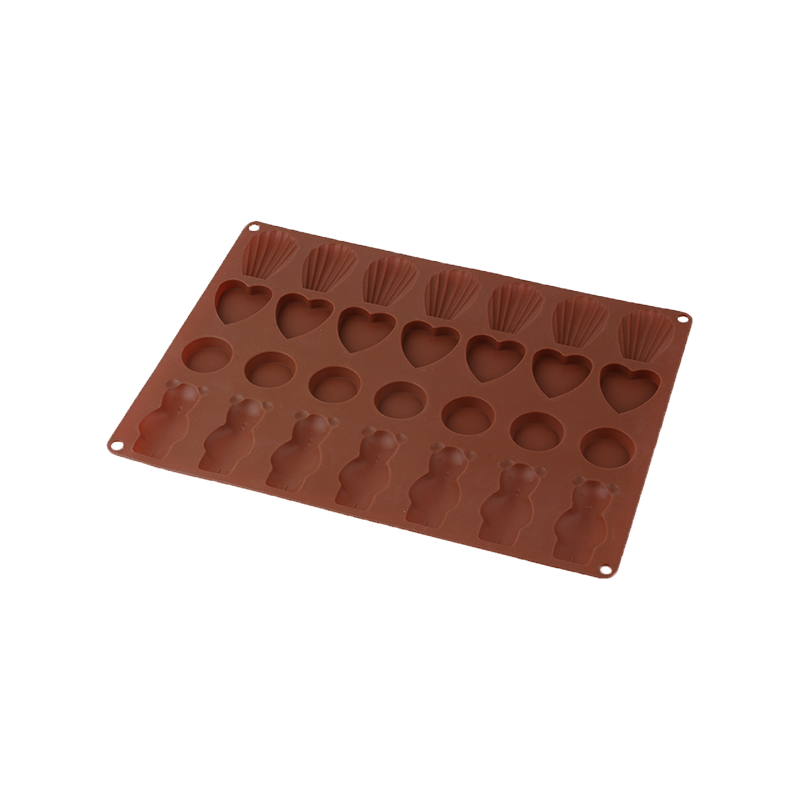

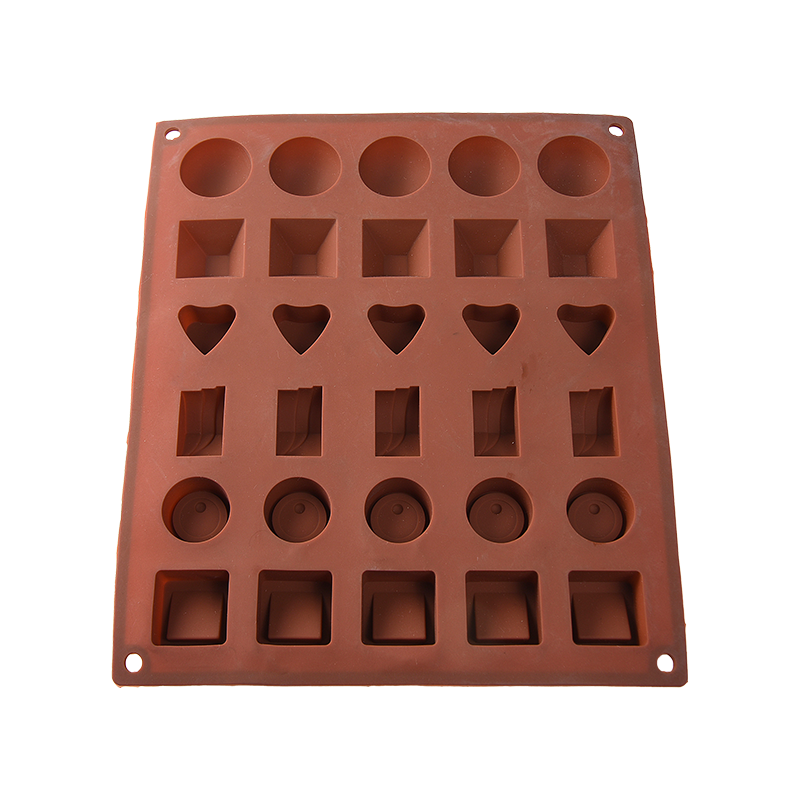

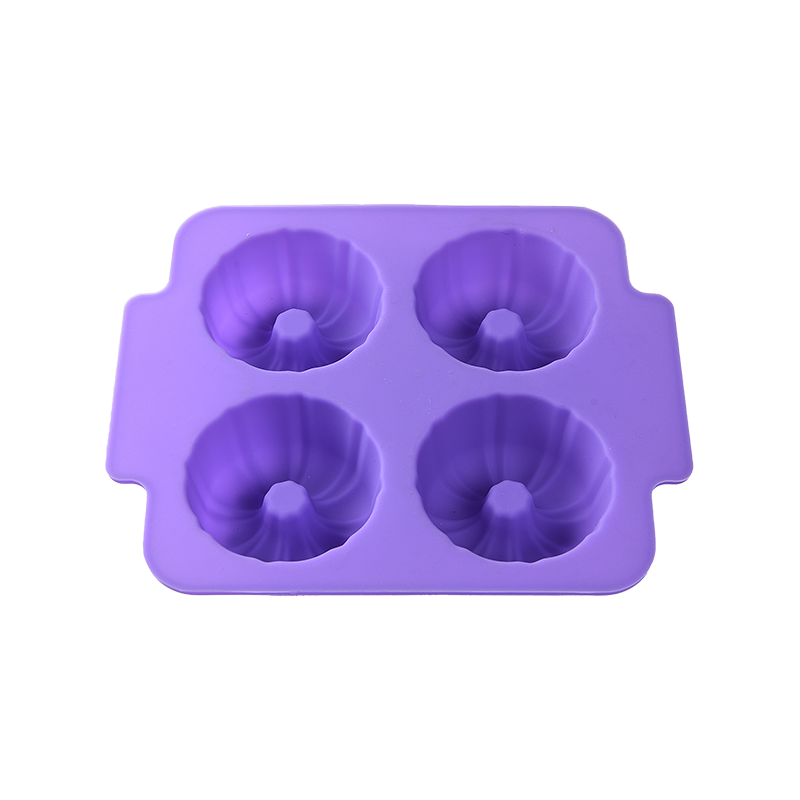

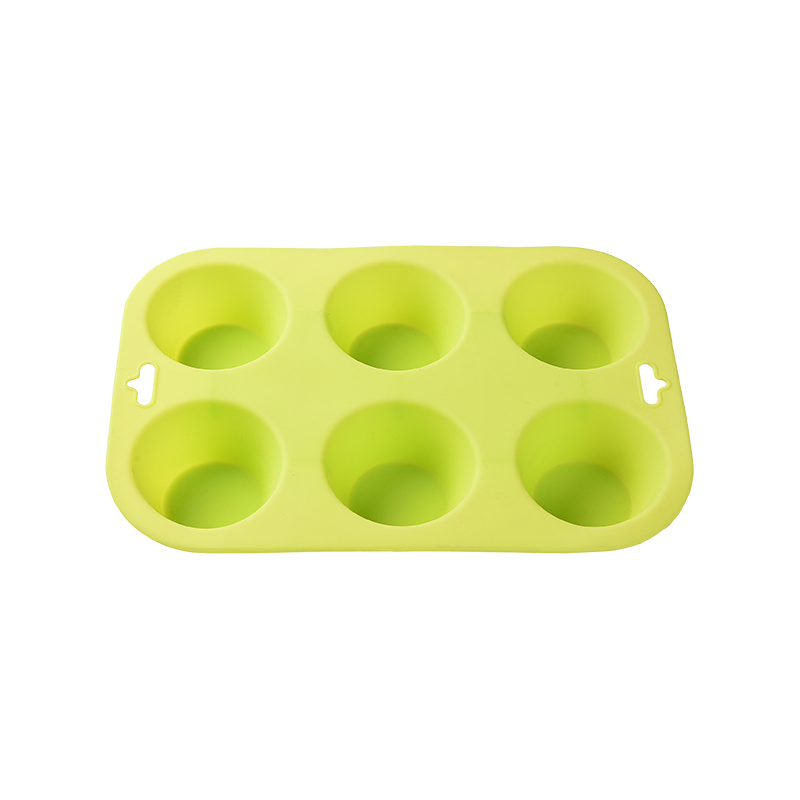

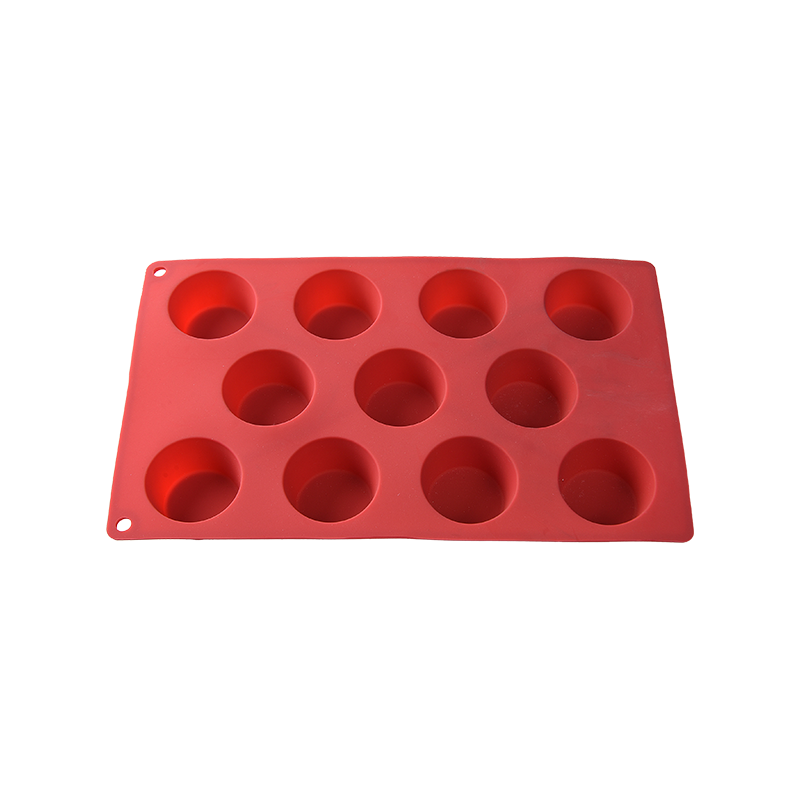

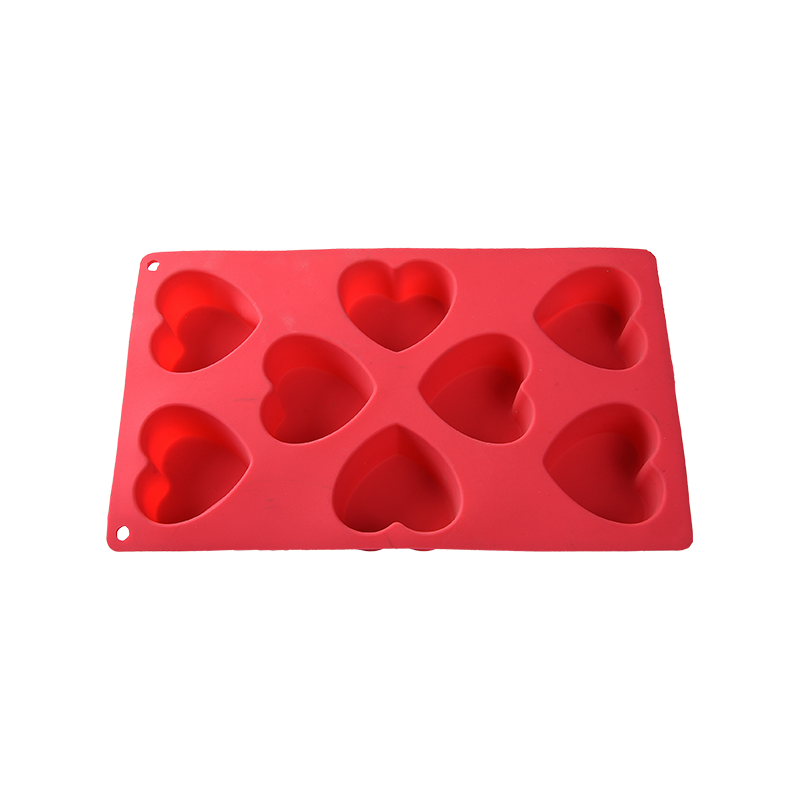

Shunyao specializes in undertaking silicone kitchen utensils, silicone toys, silicone accessories, and a variety of rubber materials, rubber tires, rubber seals, and various accessories! Undertake mold design and manufacture. As a professional China Silicone Ice Cube & Chocolate Mould manufacturers and OEM Silicone Ice Cube & Chocolate Mould factory, the company mainly produces products: silicone daily necessities, silicone kitchen utensils, silicone electrical accessories, silicone seals; rubber seals, rubber tires, seals and various accessories, and can also design and develop molds and products according to customer requirements, support OEM, ODM Order.

Shunyao is located at No. 5, Yongning Road, Dongjiao Industrial Park, Yuyao City, Zhejiang Province. The geographical location is superior and the transportation is very convenient. The company pays attention to technological transformation, actively introduces advanced technology, and is skilled in production technology. Dedication to provide our customers with products.

English

English 中文简体

中文简体